Food Safety

Church Brothers and True Leaf Farms pride themselves with having the highest integrity when it comes to Food Safety Standards. The most critical factor is having complete visibility and control of the raw material from the source. All of our products are subjected to the 7 point program outlined below.

Farm Approval

-

Pre-season risk assessment

-

Documentation review-grower GAPs, land history, adjacent land use, water source & test results, soil inputs, letter of guarantee, etc.

-

Compliance against FSMA, LGMA metrics & customer requirements

-

Implemented corrective actions/buffers if needed

Planting & Growing Compliance

-

Continual ranch monitoring & verification of implemented GAPs- animal activity/intrusion, changes in adjacent land use, review of monthly irrigation water test results, etc.

-

Completion of an annual 3rd Party GFSI Ranch Audit

-

Pre Harvest Risk Assessment (approx 4-7 days prior to harvest)

-

Pre Harvest Pathogen Testing for Leafy Greens (Salmonella & E.Coli 0157:H7)

Harvest Surveillance

-

Daily Harvest Risk Assessment to include a thorough review of the area to be harvested for any animal hazards/intrusion

-

Verification of implemented GAPs/GHPs (ex. employee hygiene, equipment/harvest tool sanitation, properly stocked restrooms, etc.)

-

Continual foreman/employee training on food safety topics such as animal hazards, employee hygiene, proper hand washing, equipment sanitation, reporting of any suspicious activity or individuals, etc.

-

Annual 3rd Party Harvest Crew Audits

-

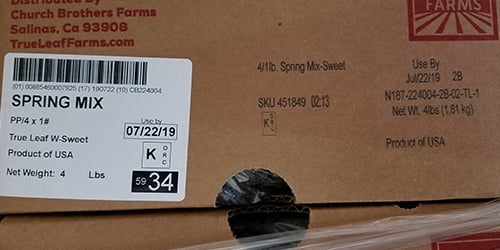

Traceability - All loads are identified with a unique block ID which establishes the grower, ranch & lot. Traceability stickers also include the harvest date and crew

Harvest Transportation & Cooling Monitoring

- Monitoring of cut to cool times

- Traceability of product leaving the field & verified upon receipt at the cooler

- Cleanliness of trucks

- Employee hygiene programs

- Monitoring of cooling process

- Sanitation of cooling tubes

Shipping & Distribution Oversight

- Traceability - Data is electronically recorded with regards to products being shipped on each order

- Monitoring of temperatures

- Cleanliness of trucks

- 3rd Party Facility Audits

- Employee hygiene programs

Value Added Process Preventative Control

- Monitoring of cut to cool times

- Traceability of product leaving the field & verified upon receipt at the cooler

- Cleanliness of trucks

- Employee hygiene programs

- Monitoring of cooling process

- Sanitation of cooling tubes

Traceability

-

Internally generated block ID for each planting

-

(identified Grower, Ranch, Lot, Variety & acres)

-

This block ID is applied in the field and follows the product all the way through receiving, cooling, processing & shipping

-

PTI, Mock Recalls, iCiX