sustainability

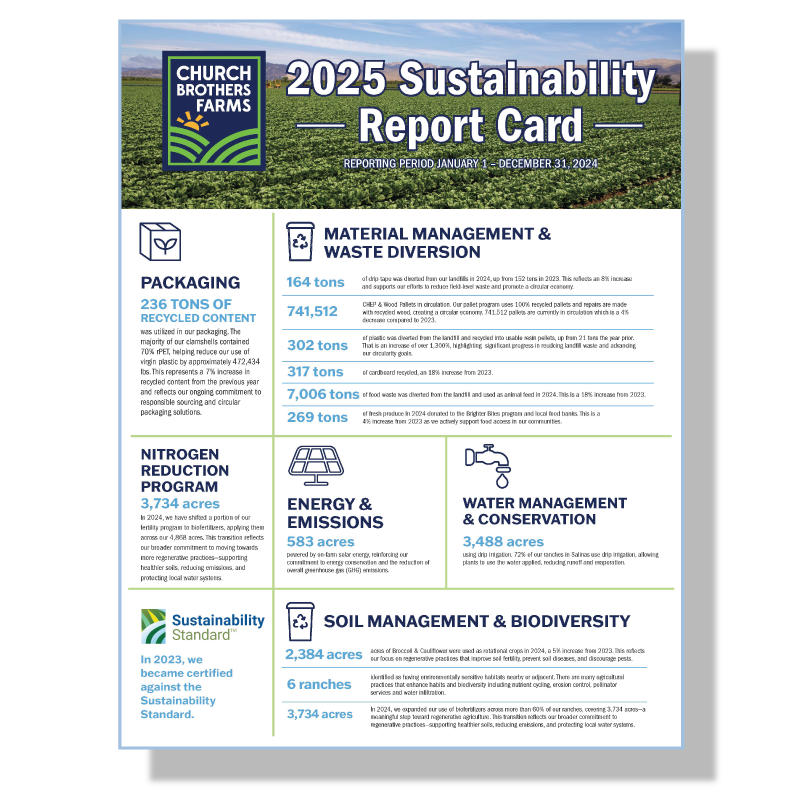

As stewards of the land, Church Brothers Farms is dedicated to protecting our natural resources for future generations. As a grower and processor, we continuously strive for improvement in efficiency and innovation from seed to plate. We are focused on practices that help us reduce waste and minimize our use of resources, all while taking care of our employees and the communities where we live.

Our mission is to grow fresh, healthy produce while protecting our roots, the land, water, and people who make farming possible. We are committed to responsible practices that build soil health, use water wisely, reduce waste, and support our communities. By combining innovation with stewardship, we provide safe, nourishing food today while preserving our resources for generations to come.